-

: 4 - 6 Workdays (DE - int. shipments may differ)

-

: 1 - 3 Workdays (DE - int. shipments may differ)

-

: 1 - 3 Workdays (DE - int. shipments may differ)

- SKU:

- 123-160

- Item weight:

- 0,10 kg

- SKU:

- 133-365

- SKU:

- 133-362

- SKU:

- 133-363

- SKU:

- SE029

- SKU:

- 323-300

- SKU:

- 323-160

- SKU:

- 123-168

- SKU:

- 323-168

- SKU:

- 177-166

Measuring Instruments – Precise Solutions for Electrical, RF & Building Biology

At PSE Priggen, you’ll find professional measuring instruments for installers, maintenance teams, laboratories, and demanding DIY users. Our range spans electrical test equipment—from digital multimeters (CAT III/CAT IV), clamp meters and voltage testers to insulation testers—plus service instruments for commissioning and troubleshooting. For building biology and diagnostics, we carry RF/EMF meters as well as devices for air quality, CO₂, humidity, and temperature. To monitor power systems, choose 3-phase power analyzers, with data loggers and panel meters rounding out your documentation toolkit. Benefit from a broad selection, expert guidance, and fast delivery—buy measuring instruments online and add the right accessories in one go.

Electrical Test Equipment: Multimeters, Clamp Meters, Voltage & Insulation Testing

For installation and fault-finding, rely on digital multimeters (CAT III/CAT IV), clamp meters for non-intrusive current, two-pole voltage testers, and insulation testers for safety checks. Rugged housings, clear displays, and safety categories aligned to standards deliver accurate, repeatable results—at outlets, in control cabinets, or directly on machines.

HF/EMF Meters for Building Biology & Diagnostics

Our HF meters capture high-frequency sources such as Wi-Fi, DECT, cellular (incl. 5G) and assess low-frequency fields from building wiring. Ideal for building biologists, surveyors, and sensitive residential/work environments—from broadband detectors for rapid screening to analyzers with frequency weighting. Measure exposure, document findings, and define meaningful mitigation steps.

3-Phase Instruments & Power Analysis: Load, Quality, Efficiency

Use three-phase analyzers to monitor voltage, current, power, power factor, harmonics, and energy consumption. This helps smooth load peaks, identify power-quality issues, and boost system efficiency—across manufacturing, building automation, and EV charging infrastructure. Long-term logging accelerates root-cause analysis and compliance reporting.

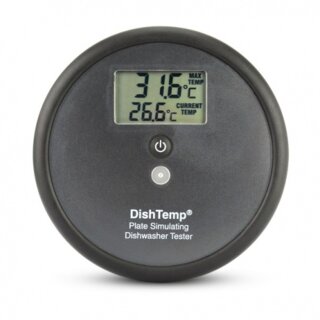

Temperature Measurement & Data Loggers: HACCP, Process & Lab

For food safety, laboratory, and industrial tasks, choose contact/infrared thermometers and data loggers for temperature and humidity. HACCP-focused models support traceability; interfaces and software simplify end-to-end documentation. Combine probes, sensors, and loggers by range, accuracy, and response time—from goods-in to process monitoring.

Indoor Air Quality, CO₂ & Humidity: Healthy Spaces Made Measurable

Assess indoor air quality in offices, schools, clinics, and homes with CO₂, humidity, and temperature meters. Threshold indicators and logging make ventilation strategies verifiable and lead to clear recommendations. Add material moisture meters to identify damp problems early and reduce mold risk.

Panel Meters & Built-In Instruments: Make Values Visible

Our panel meters/built-in instruments present voltage, current, frequency, temperature, or process signals right on your control panel. From simple digital readouts to scalable transmitters, integrate measurements neatly into existing control systems—with alarm outputs and interfaces for downstream processing.

Accessories, Calibration & Service: Everything from One Source

The right accessories—test leads, probes, clamp adapters, sensors—and calibration certificates help you achieve maximum accuracy. Our expert support assists with product selection, standards, and CAT safety categories (CAT II/III/IV). Optional calibration and documentation packages keep your measurements audit-ready at all times.

Industries & Use Cases: From Trades to Research

Our solutions serve electrical contractors, facility management, industry, utilities, pharma/life-science, food, and education & research. Typical scenarios: commissioning & maintenance, energy/load analysis, quality & hygiene control, building biology assessments, and long-term monitoring for compliance and Efficiency.

FAQ on measuring instruments

What is a measuring instrument and what is it used for?

What is a measuring instrument and what is it used for?

A measuring instrument is an instrument used to determine physical quantities such as length, weight, temperature, pressure, or electrical current. It is used in various fields such as science, industry, medicine, and crafts to perform precise measurements and obtain accurate data. Examples of measuring instruments include thermometers, scales, voltmeters, and calipers. They help ensure quality control, optimize processes, and comply with safety standards.

What types of measuring instruments are there?

What types of measuring instruments are there?

There are different types of measuring instruments, each serving a specific purpose. The most common include:

Length measuring instruments: rulers, calipers, micrometers.

Weight measuring instruments: scales, spring scales.

Temperature measuring instruments: thermometers, infrared thermometers.

Pressure measuring instruments: manometers, barometers.

Electrical measuring instruments: multimeters, oscilloscopes.

Volume measuring instruments: graduated cylinders, burettes.

Moisture measuring instruments: hygrometers, humidity meters.

Speed measuring instruments: tachometers, radar.

Light measuring instruments: lux meters, photometers.

Sound measuring instruments: decibel meters, sound level meters.

These instruments help you take precise measurements in various fields.

How does a measuring device work?

How does a measuring device work?

A measuring device works by measuring physical quantities such as length, temperature, pressure, or current and converting them into an easy-to-read form. It can be mechanical, electrical, or digital. An analog meter displays values on a scale, while a digital meter presents the values numerically. Sensors within the device detect the quantity being measured and convert it into a signal, which is then displayed. You should ensure that the measuring device is calibrated regularly to ensure accurate results.

What should you consider when purchasing a measuring device?

What should you consider when purchasing a measuring device?

When purchasing a measuring device, you should pay attention to the following points:

Measurement accuracy: Pay attention to the device's accuracy and tolerance values.

Measuring range: Make sure the measuring range meets your requirements.

Quality: Choose a device from a reputable manufacturer to ensure a long service life.

Ease of use: The device should be easy to use and have a clear display.

Calibration: Check if the device is calibrated or can be easily calibrated.

Features: Consider what additional features, such as memory or data transfer, you need.

Value for money: Compare different models to find the best value for money.

Warranty and support: Pay attention to the warranty conditions and customer support.

These aspects will help you choose the right measuring device for your needs.

How is a measuring device properly calibrated and maintained?

How is a measuring device properly calibrated and maintained?

A measuring device is properly calibrated and maintained by following these steps:

Calibration:

- Identify the reference material or reference values required for calibration.

- Ensure the measuring device is clean and free of contaminants.

- Perform the calibration according to the manufacturer's instructions.

- Document the calibration results and compare them with the reference values.

- If deviations exist, adjust the measuring device accordingly.

- You can also return the measuring device to us. We will calibrate it for you and issue a calibration certificate.

Maintenance:

- Clean the measuring device regularly to ensure accurate measurements.

- Inspect the device for physical damage and wear.

- Replace worn or damaged parts.

- Perform regular functional tests.

- Store the measuring device under the conditions recommended by the manufacturer.

Regular calibration and maintenance ensure the accuracy and longevity of your measuring device.

What are the benefits of using a measuring device?

What are the benefits of using a measuring device?

Using a measuring device offers numerous advantages. First, it enables precise and reliable measurements, which are essential for many applications. Second, it saves time because measurements can be performed quickly and efficiently. Third, it increases safety because accurate measurements can identify potential hazards. Fourth, it improves the quality of products and services through precise monitoring and adjustment. Finally, it contributes to cost reduction by optimizing material consumption and minimizing waste. A measuring device is therefore an indispensable tool in many industries.

Are there special safety instructions when handling measuring devices?

Are there special safety instructions when handling measuring devices?

Yes, there are important safety instructions when handling measuring devices:

Calibration: Check the calibration of the measuring device regularly to ensure accurate results.

Instructions for use: Read and understand the manufacturer's instructions for use completely.

Protective clothing: Wear appropriate protective clothing, especially when performing chemical or electrical measurements.

Environment: Maintain a clean and dry work environment to avoid inaccurate measurements.

Storage temperature: Maintain the recommended storage temperatures to avoid damage to the device.

Handling: Handle the device with care to avoid physical damage.

Zeroing: Check the zeroing of the device before each measurement to ensure accurate results.

These instructions help extend the life of the measuring device and increase safety.

Which measuring instruments do I need for common electrical tasks?

For installation and troubleshooting: a digital multimeter (choose CAT III/CAT IV by location), a clamp meter for load current, a voltage tester for quick checks, and an insulation tester for safety verification.

What are RF/EMF meters used for?

They assess high- and low-frequency fields (e.g., Wi-Fi, DECT, 4G/5G and mains-related fields). Ideal for building biology surveys, documentation, and recommendations in homes and workplaces.

When do I need a 3-phase analyzer or power quality meter?

Whenever you run three-phase systems and must optimize load distribution, analyze power/energy, detect harmonics or power-quality issues, and troubleshoot intermittent faults.

How can I document temperature and quality reliably?

Use data loggers and thermometers (contact or IR) for HACCP, lab, or process tasks—automated logging, clear reports, and long-term storage make audits straightforward.

Does PSE offer consulting and accessories?

Yes—get expert guidance plus sensors, probes, panel meters, leads, and calibration services tailored to your measurement task.