inVentia Telemetry, PLC, GSM

inVentia, Manufacturer of GSM based Telemetry Modules, PLC Small Control Systems, Process Controls and Location Tracking Products

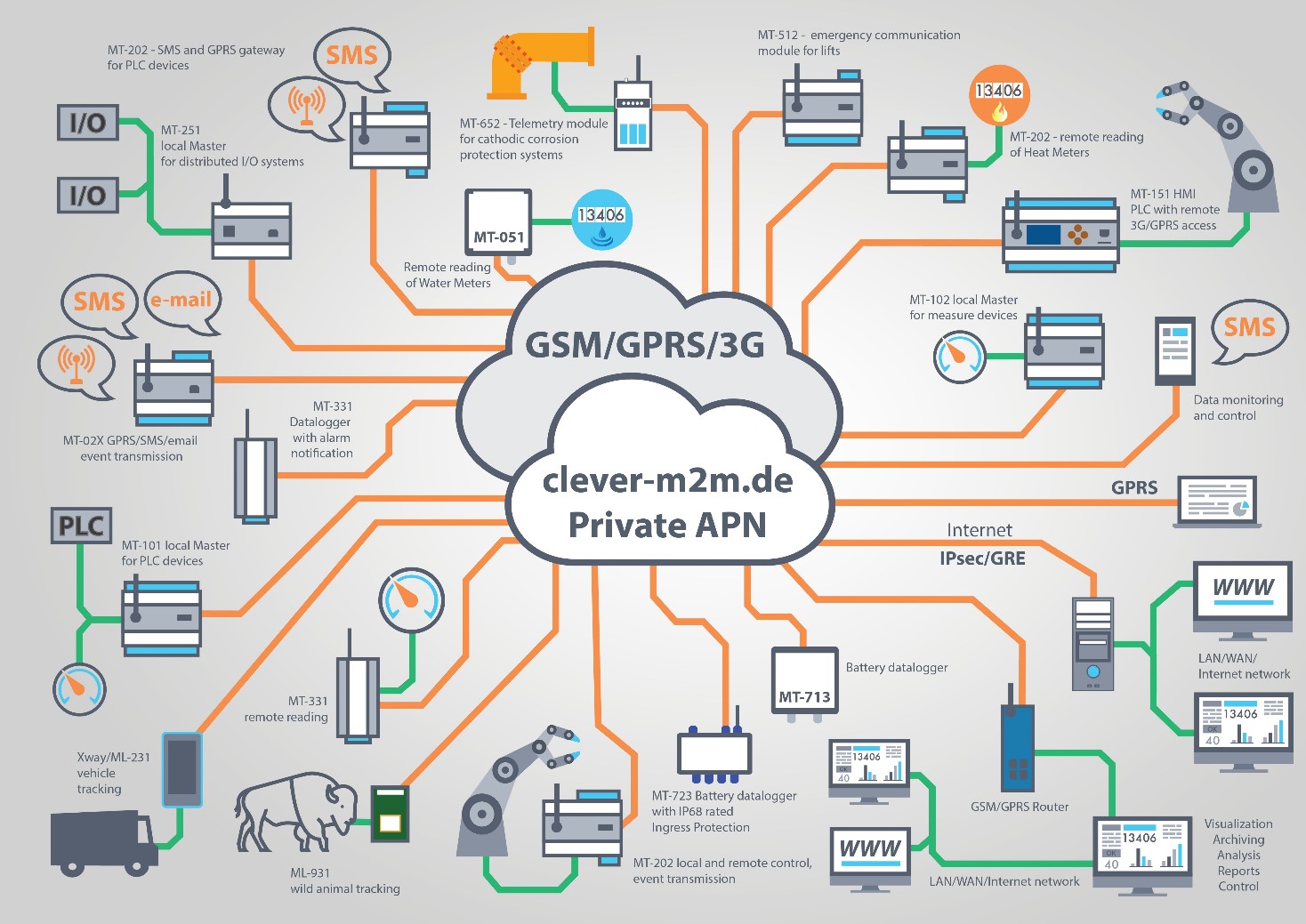

inVentia is a manufacturer and global vendor of telemetry, process control and location tracking products, based on GSM/GPRS and GPS technologies.

Founded in 2001 and located in Warszawa, Poland, inVentia has become one of the leaders in professional GPRS telemetry and small control systems with PLC functionality. The product range includes not only telemetry and localization modules but also open architecture solutions based on proven industrial standards.

inVentia delivers easy to use configuration and system integration tools providing open connectivity to customer SCADA systems, relational data bases and data management systems. The products work with the MQTT message protocol and find applications in Industry 4.0, IoT,

water and sewage management, heat and professional power industry, transport, facilities protection, agriculture and horticulture, AndonBoard, machine data collection, production control and downtime monitoring.

Example applications:

- Monitoring and control of pumping stations

- Monitoring of gas reduction stations

- Remote reading of media consumption (water, heat, gas, electricity)

- Non-contact temperature control of elements in the electrical switchboards

- Location of vehicles and containers

- Measurement of water level (in wells, water intakes, rivers)

- Measurement of water tanks filling

- Monitoring of overhead transmission lines

- Monitoring of lifts operations, monitoring of temperature and humidity in silos, data transmission from meteorological stations

- Air pollution measurements

- Monitoring parameters and control of the cathodic protection installation of pipelines, tanks and other metal structures buried in the ground or immersed in water

- Large scale irrigation systems for crops, fruit and vegetable farms, forest areas and gardens

More than 80,000 Modules Sold worldwide

inVentia have already sold over 80,000 modules to 53 countries in the world. The market succes results not only from the high quality products and their innovative functionality, but also from the consequently implemented concept of solutions that are freely configurable by the user. All products are designed and developed by a team of industrial automation, telocommunication and IT specialists with long-term engineering experience. The telemetry modules of the MT series won prestigious awards, i.e. the Gold Medal on the AUTOMATICON Fair and the Grand Prix on the WODKAN Fair.

ISO 9000 Certification, 3 Years Warranty

The designing, manufacturing, sales and services procedures performed by inVentia has been certified according to the ISO 9000:2008 Quality Management System.

inVentia grants a 3 years warranty on their products.

What is Codesys®?

CODESYS® is an integrated controller programming environment compliant with the international IEC 61131-3 standard. CODESYS® has extensive programming functionalities such as support for the most popular programming languages in automation (LD, FBD, SFC, ST, C), extensive code testing capabilities, ease of code portability between different architectures, and support for multiple communication protocols. The software is constantly being developed by the numerous PLC manufacturers’ community.

The ability to use several programming languages within a single project allows you to choose the best language for the task at hand, and the ability to monitor and push variables significantly facilitates diagnostics and testing of the functionality of the written program.

The visualization tool allows you to create screens presenting the state of a process as: animations, graphics, tables and charts. It is possible to set control values from the visualization level.

A wide range of available libraries allows to expand the functionality of the programming tool adequately to the user needs and the task at hand. The ability to define your own functions and function blocks significantly simplifies programming and makes the program itself more readable.

CODESYS® advantages:

- IEC 61131-3 compliant – available languages include ST, LD, FBD, SFC, as well as C

- Extensive diagnostic tools

- Ability to expand individual functionalities by adding libraries

- Ease of code portability between different programs

- Built-in visualization tool with ready set of elements for the process monitoring and controlling

- Ability to define custom functions and function blocks

- Documentation tool

- Support for multiple communication protocols

What does a MT module gain by using CODESYS® software?

- Writing programs using the most popular programming languages in automation, such as Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), or Sequential Function Chart (SFC). The possibility of using several programming languages within one project allows you to choose the best language for a given task.

- Access to a rich set of ready-made libraries extending the functionality of the environment. This speeds up the development process and facilitates the development of advanced applications.

- Compliance with the industry-widely accepted IEC 61131-3 standard provides an intuitive environment for new MT users.

- An extensive debugging tool allows you to monitor and force variables, and thus easier testing of the written program either directly on the device or using simulator.

- Possibility of using several programming languages within one project.

Sale only to Business Customers!

Please note that we do not deliver these products to private customers, but only to business customers!